Industry Best Practices

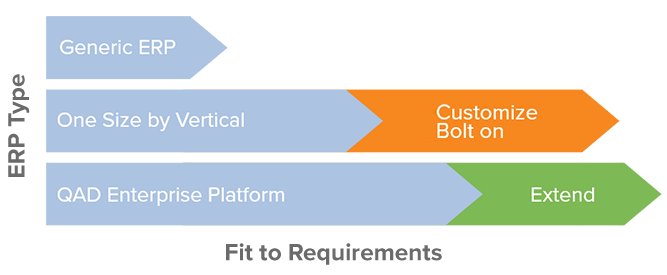

Manufacturers have distinct business processes that differentiate them in the market, while at the same time, adhering to industry-specific requirements, mandated regulations and standards. It’s the job of the ERP to embed and deliver industry best practices to meet those needs. Manufacturers are best served by ERP systems that combine industry best practices with the agility to rapidly adapt them to meet changing business challenges.

Integrated Global Compliance

Industry-specific Process Maps

Effective On Boarding

QAD Adaptive ERP embeds industry best practices focused on the unique needs of 24 specific segments within six manufacturing industries. These best practices have been developed through QAD’s deep industry expertise and active involvement with industry standards organizations. This insight results in the latest industry best practices in our products and services, driving faster implementations and greater fit out-of-the-box.

Manufacturing Best Practices Integrated for Global Compliance and Quality Standards

QAD's strategy of focusing on manufacturing industry verticals helps ensure QAD solutions are best-fit for target industries. Active participation in the industry ecosystems helps QAD stay up-to-date on the latest trends and best practices, resulting in integrated industry best practices conforming to the specific requirements of the applicable industry segment.

What are Best Practices?

A best practice is a process, method or technique that has consistently been proven effective compared to other approaches and which has been duplicated across several use cases or examples. To be a ‘best practice’, the practice must produce better results than other approaches or be considered the standard way of doing things.

Why are Manufacturing Best Practices Important?

Along with deploying business practices that are viewed as being the most effective, best practices deliver results that include improved quality performance, lower supply chain costs, greater productivity, higher customer satisfaction and a boost in profitability. Best practices can apply across an entire organization including supply chain, health and safety, quality, human resources, finance, legal, global trade and numerous other areas. Additionally, best practices help address regulatory and other standards that can include CGMP (Current Good Manufacturing Practice), MMOG/LE (Materials Management Operations Guidelines/Logistical Evaluation), OSHA (Occupational Safety and Health Administration), SOX (Sarbanes-Oxley Act) and other functional and geographic regulatory requirements.

Best Practices for Manufacturing

- Lean Manufacturing

- Initiate Preventive Maintenance

- Enable Automation

- Implement a Quality Management System

- Track Global Trade Compliance and Environmental Standards

- Maintain a Current Operational Restart Checklist

QAD Enables Brose Thailand to Focus on a Strategy of Continuous Improvement

Find out how Brose Thailand reduced its shipping costs, with fewer inventory overages and better planning, by upgrading to QAD Enterprise Edition.

Learn More

QAD EQMS Improves Quality Management for Customer-driven Business

Learn how adding QAD EQMS to Cascade Engineering's ERP saved the plastic injection molding manufacturer time and money.

Learn More

Effective On Boarding

Get a scalable, predefined process with predictable costs for your next QAD ERP solution implementation.

Focus on manufacturing best practices without unnecessary functionality for faster time to value.

How Can We Help You?

Are you interested in exploring QAD Adaptive Applications? Do you have specific questions, comments or feedback? Get in touch with us!

Thank you for reaching out to QAD! Your inquiry has been forwarded to the appropriate representative who will contact you shortly.

In the meantime, for more information on how we can work together toward building an Adaptive Enterprise please subscribe to the QAD Blog for commentary on the latest news and announcements from QAD and the industry.

If you would like to change your message settings, visit our Subscription Preference Center.